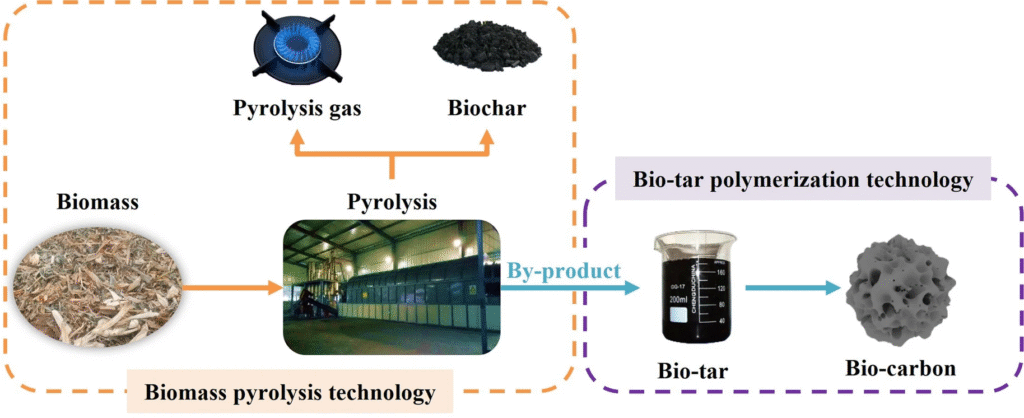

Bio-tar, a notorious by-product of biomass energy, can be re-engineered into bio-carbon, a valuable material for clean energy and environmental protection. Researchers are developing methods to transform this waste into useful resources, potentially cutting emissions and creating profit. This article delves into the process and implications of this innovation, exploring sustainable materials toward a cleaner future.

Understanding Bio-Tar and Its Challenges

Bio-tar is a complex substance emerging from the process of biomass energy production. It is essentially a by-product, but its characteristics pose significant challenges. Understanding its origins, composition, and associated challenges is essential to appreciating its role in the energy industry and the efforts to transform it into a valuable resource.

Origins and Composition of Bio-Tar

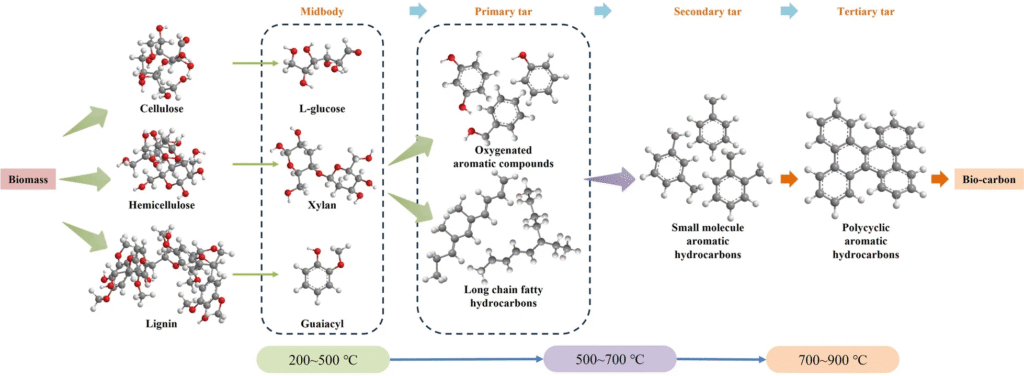

Bio-tar forms during the pyrolysis of biomass—a process that involves the thermal decomposition of organic material at elevated temperatures in the absence of oxygen. The primary goal of pyrolysis is to convert biomass into bio-oil, a liquid fuel. However, bio-tar is an unavoidable by-product of this conversion process. It is a sticky, viscous substance composed mainly of a complex mixture of hydrocarbons, oxygenated compounds such as phenols and ethers, high molecular weight polyaromatic hydrocarbons (PAHs), and other organic compounds.

Bio-tar’s chemical composition varies significantly depending on the type of biomass used and the specific conditions of the pyrolysis process, such as temperature, heating rate, and residence time. These variations influence bio-tar’s physical properties, including viscosity and density, impacting how it interacts with equipment and systems used in bioenergy production.

Challenges Posed by Bio-Tar

The presence of bio-tar in bioenergy systems is problematic for several reasons. One of the most pressing issues is its tendency to **clog pipelines**. Its sticky, viscous nature makes it prone to adhering to the interiors of pipelines and other mechanical components. Over time, this accumulation reduces flow efficiency, increases the risk of blockages, and necessitates frequent maintenance interventions.

Additionally, bio-tar can damage equipment. The abrasive nature of PAHs and other compounds can lead to the accelerated wear and corrosion of equipment. This is especially problematic for sensitive components like valves and sensors that are integral to maintaining precise control over bioenergy processes. Frequent repairs and replacements increase operational costs and lead to downtime, which further impacts the economic viability of bioenergy production.

Bio-tar also poses significant environmental risks. If not managed properly, bio-tar may leak or spill, leading to soil and water contamination. PAHs and other toxic compounds in bio-tar can have persistent and harmful impacts on ecosystems. The potential for bio-tar to contribute to pollution is a crucial concern that necessitates robust management strategies.

Historical Challenges and Attempts at Mitigation

The bioenergy industry has historically grappled with the challenges posed by bio-tar. Efforts to manage its negative impacts have involved various mitigation strategies throughout the years. One common method has been physical separation techniques. These involve filtering or distilling bio-tar from bio-oil during or after the pyrolysis process. While effective to some degree, these methods often struggle to handle all the complex organic compounds present, and efficiency can vary greatly with differing biomass types.

Researchers have also explored chemical treatment options. Catalytic cracking, which involves breaking down large molecules into smaller, more manageable components, has been investigated. Various catalysts, such as zeolites and metallic oxides, have been examined for their effectiveness in enhancing the breakdown process. However, cost and scalability remain significant barriers to widespread adoption of these techniques.

Advanced Technological Approaches

Technological advancement has also led to the development of more innovative approaches to handling bio-tar. For instance, plasma technology is currently being explored as a potential solution. Plasma processes can facilitate the breakdown of complex hydrocarbons efficiently, converting them into simpler, less environmentally harmful substances. While still in the experimental stages, plasma technology offers hope for a more efficient and less costly solution to the bio-tar problem.

Another approach being considered is the use of biological treatments. Certain microbial communities have shown potential in breaking down organic compounds within bio-tar. Biological treatments could offer a more sustainable and energy-efficient option. However, further research and development are required to optimize these methods for industrial applications.

Despite these promising avenues, it is undeniable that complete elimination or conversion of bio-tar into non-problematic substances remains a challenge. The development of comprehensive strategies requires significant R&D investment, collaboration across sectors, and policy support to facilitate large-scale application.

Coordinating Efforts Across the Industry

As biomass energy production continues to expand, addressing the challenges of bio-tar is ever more critical. Institutions and companies are increasingly investing in research to devise effective solutions. Support from environmental policy frameworks also plays a pivotal role in encouraging cleaner bioenergy production practices.

In summary, bio-tar presents formidable challenges to the bioenergy industry, including infrastructure damage, economic burdens, and environmental threats. While historical and emerging methods to mitigate these issues show promise, concerted efforts are required for sustainable integration. Understanding the complex nature of bio-tar and refining strategies to manage it are vital steps in advancing biomass energy production toward a cleaner and more sustainable future.

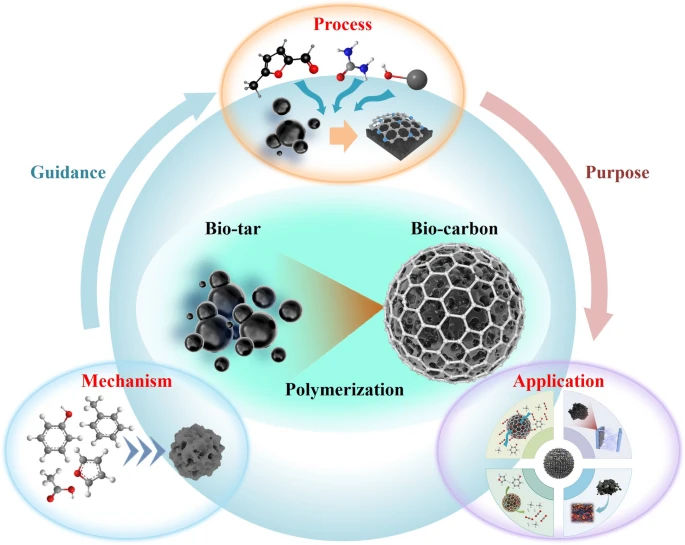

The Science Behind Bio-Carbon Conversion

The conversion of bio-tar into bio-carbon is a transformative chemical phenomenon that addresses both environmental and industrial challenges. By understanding and controlling the underlying processes, researchers can harness the potential of bio-carbon as a sustainable energy solution. The journey of bio-tar towards becoming bio-carbon involves intricate chemical reactions, particularly focusing on polymerization and the influence of oxygen-rich compounds.

Bio-tar, a product derived from the thermal decomposition of biomass, contains a complex mixture of organic compounds. These compounds include carbonyls, furans, phenols, and a variety of other organic molecules. When bio-tar undergoes chemical transformations, its composition can be refined into valuable bio-carbon. Understanding these reactions is crucial for optimizing bio-carbon production, ensuring it possesses the desired properties for its various applications.

At the heart of the bio-tar to bio-carbon conversion is polymerization. This process involves the linkage of small molecular units into larger, more complex structures. During this transition, carbon-rich molecules from bio-tar organize into long chains or networks. Polymerization in this context is driven by thermal or catalytic means. The introduction of heat or catalysts serves to activate the reactions within bio-tar, enabling the formation of stable, carbon-rich matrices.

A key factor in these reactions is the presence of oxygen-rich compounds such as carbonyls and furans. These compounds play a significant role in dictating the reaction pathways. Carbonyls, identified by the presence of a carbon-oxygen double bond, can undergo various transformations under thermal conditions. They are particularly reactive and can form intermediary products which then progress into polymerized forms. Furans, characterized by their aromatic ring structures, contribute to building more complex carbon frameworks. The reactivity of furans is crucial in forming cross-linked architectures that enhance the structural integrity of the resulting bio-carbon.

Controlling these reactions allows for the production of bio-carbon with specific traits. For instance, varying the temperature and duration of the heating process can lead to the formation of different types of carbon structures. High temperatures generally result in more graphitic and orderly carbon materials, whereas lower temperatures may lead to amorphous carbon. Additionally, the choice of catalyst, if employed, considerably affects the formation and characteristics of bio-carbon.

Researchers employ a variety of methods to optimize these chemical transformations. One approach involves experimenting with different catalysts that promote selective reactions. By using catalysts, researchers can lower the energy barriers for reactions to occur and increase the efficiency of the process. Catalysts such as metal oxides and acidic materials have shown promise in facilitating the polymerization of bio-tar components.

Another method to optimize the process is through adjusting the heating rate and environment. A controlled heating process can enhance the yield of specific types of bio-carbon. Emerging techniques such as microwave-assisted pyrolysis offer a more uniform heating mechanism, which can improve the quality of the produced bio-carbon. This technique also provides a faster heating rate, which often leads to superior material characteristics compared to conventional methods.

Analyzing the properties of the components in bio-tar is also pivotal. Techniques such as gas chromatography and mass spectrometry are employed to study the composition of bio-tar. Such analysis helps in understanding the proportions of carbonyls, furans, and other compounds present, allowing better prediction and control of the resultant bio-carbon properties.

Additionally, advanced molecular modeling and simulation techniques aid in understanding the complex interactions within bio-tar during its transformation. These tools can predict how different conditions will affect molecular dynamics and provide insights into optimizing reaction conditions.

Further advancements in this field involve developing hybrid methods that combine thermal and catalytic approaches. By integrating these techniques, researchers aim to enhance the efficiency and effectiveness of bio-tar conversion to bio-carbon. Such synergistic methods promise increased yields, better-quality bio-carbon, and reduced processing times.

While much has been done, the research is ongoing to find even more efficient and scalable methods for converting bio-tar into bio-carbon. By continuously refining the understanding of the chemical processes at play, the potential for utilizing bio-carbon in various industrial applications can be fully realized. This would not only mitigate the environmental hazards posed by bio-tar but also unlock a valuable resource for sustainable development.

As researchers explore these avenues, it becomes evident that the transformation of bio-tar into bio-carbon is more than just a chemical reaction. It represents a pivotal step towards achieving a sustainable and environmentally friendly solution for energy needs. By addressing the challenges associated with bio-tar and optimizing the chemical processes involved, the bio-carbon revolution can pave the way for significant advancements in clean energy.

For those interested in diving deeper into the quantum mechanics underpinning these transformations, exploring quantum computing’s role in simulating complex chemical reactions might be of interest. For more on this fascinating interplay, visit a detailed guide on the efficiencies of quantum computing in chemical reactions.

Applications and Advantages of Bio-Carbon

Bio-carbon, with its porous structure and versatile chemical properties, offers a wealth of applications that address both industrial demands and environmental concerns. As we delve into its various uses, it’s essential to recognize how bio-carbon serves in capacities such as adsorbents, electrode materials, catalysts, and clean-burning fuels.

Bio-carbon’s role as an adsorbent is pivotal, especially in water purification. The porosity of bio-carbon makes it incredibly effective at capturing impurities. This capability is paramount when considering the increasing strain on clean water resources. By utilizing bio-carbon, we can target and remove pollutants, leading to cleaner and safer water. Moreover, when implemented in wastewater treatment facilities, bio-carbon can significantly improve the efficiency and reduce the costs associated with traditional filtration methods.

In the realm of energy storage, bio-carbon proves indispensable as an electrode material. Its high conductivity and large surface area enhance the performance of batteries and supercapacitors. By replacing conventional carbon-based materials with bio-carbon, energy storage devices can achieve faster charge times and longer lifespans. This innovation plays a critical role in the ongoing development of sustainable energy technologies, crucial for reducing reliance on fossil fuels and minimizing environmental impact.

Bio-carbon also excels as a catalyst in chemical reactions. Its ability to facilitate reactions without being consumed is beneficial for various industrial processes, including those producing plastics and pharmaceuticals. Furthermore, bio-carbon’s catalytic properties allow for more efficient energy conversion processes, enhancing the sustainability of industrial operations. This use not only reduces energy consumption but also lessens the carbon footprint associated with many chemical manufacturing processes.

In terms of sustainable fuel sources, bio-carbon has marked its territory as a clean-burning fuel option. When compared to conventional coal, bio-carbon offers a significantly lower emission profile. Its combustion process results in reduced CO2 emissions, making it an appealing alternative as industries seek to decarbonize. Harnessing bio-carbon as a fuel aligns with global targets of reducing greenhouse gases and combating climate change.

The economic benefits of bio-carbon applications are noteworthy. For instance, industries incorporating bio-carbon can witness substantial savings on raw material costs. The transition to bio-carbon may involve initial investments, but the long-term financial returns, coupled with subsidies and incentives often provided for sustainable practices, can lead to profitability. Bioenergy plants, in particular, stand to benefit from these developments. They are well-positioned to utilize bio-carbon, turning waste into an asset and facilitating a circular economy.

Environmental advantages of bio-carbon cannot be overstated. As it reduces the dependence on virgin raw materials and lowers pollution levels, bio-carbon embodies a move towards more sustainable industrial practices. Its application helps mitigate the adverse effects of climate change, especially with the growing evidence suggesting bio-carbon’s net-positive impact. Recent assessments underscore the contribution of bio-carbon to achieving carbon neutrality, positing it as a cornerstone of future energy solutions.

As we further explore the potential of bio-carbon, ongoing research and assessment are vital to unlocking even more applications. With advances in material science, the customization of bio-carbon properties for specific industrial needs becomes more feasible. This adaptability can spur innovations across diverse sectors, enhancing the resilience and sustainability of industries globally.

The promise of bio-carbon extends beyond theoretical discussions, calling for practical, actionable commitments from stakeholders at every level. Policymakers are urged to support research and development initiatives, providing the necessary framework for bio-carbon technology adoption. Industries must reassess their processes, incorporating bio-carbon to leverage its benefits fully. By integrating bio-carbon into strategic plans, businesses can achieve sustainable growth while contributing to wider environmental goals.

For a more comprehensive understanding and further exploration into bio-carbon and its applications, readers can refer to resources focused on sustainable energy solutions. These publications offer in-depth analyses and case studies that provide valuable insights into the myriad possibilities that bio-carbon presents.

Empowered with knowledge and motivated by the vision of a sustainable future, we are in a unique position to harness the power of bio-carbon effectively. By doing so, we pave the way for an era defined by responsible resource management, economic vitality, and ecological balance. Let’s seize the opportunity before us, embracing the bio-carbon revolution as a means to redefine our approach to energy and industrial processes.

Conclusion

Bio-tar, once a costly waste, can now become bio-carbon, offering a sustainable path forward for clean energy and environmental enhancement. Through scientific innovation, this conversion not only addresses the bioenergy sector’s long-standing issues but also paves the way for profitable and eco-friendly solutions. Continued research and collaboration can unlock bio-carbon’s full potential across various industries.

Journal Reference:

- Yuxuan Sun, Jixiu Jia, Lili Huo, Xinyi Zhang, Lixin Zhao, Ziyun Liu, Yanan Zhao, Zonglu Yao. Preparation of bio-carbon by polymerization of bio-tar: a critical review on mechanisms, processes, and applications. Biochar, 2025; 7 (1) DOI: 10.1007/s42773-025-00477-9